Lesi sihloko sizokwethula imibono yokuklama kanye nenqubo yokucubungula isembozo sebhokisi lesidlo sasemini seplastiki ngokuningiliziwe, kanye nesakhiwo sezingxenye zepulasitiki, izinto zokuhlaziya okuphelele, ukuklama okunengqondo kobuchwepheshe besikhunta.

Amagama abalulekile: isikhunta sokujova;Isikhafithini.Inqubo yokubumba

Ingxenye yokuqala: Ukuhlaziywa kwenqubo yezingxenye zepulasitiki nokukhethwa okuyinhloko komshini womjovo

1.1Izinto zokusetshenziswa kanye nokuhlaziywa kokusebenza kwebhokisi lesidlo sasemini lepulasitiki

Leli bhokisi lesidlo sasemini lepulasitiki liwumkhiqizo wepulasitiki ojwayelekile empilweni yansuku zonke, ikakhulukazi esetshenziselwa ukubamba ukudla.Uma kucatshangelwa ubukhulu bokusetshenziswa kwayo, ukuhlaziya okuphelele kokusebenza kwamapulasitiki ahlukahlukene, ukukhethwa kwezinto ezibonakalayo ze-polypropylene (PP).

I-Polypropylene (ipulasitiki ye-PP) iwuhlobo lokuminyana okuphezulu, alikho iketango laseceleni, i-crystallization ephezulu ye-polymer eqondile, inezici ezinhle kakhulu ezibanzi.Uma kungenambala, okumhlophe ku-translucent, waxy;Ilula kune-polyethylene.Ukungafihli nakho kungcono kune-polyethylene.Ukwengeza, ukuminyana kwe-polypropylene kuncane, amandla adonsela phansi athile angu-0.9 ~ 0.91 amagremu/cubic centimeter, amandla okukhiqiza, ukuqina, ukuqina nokuqina, amandla okucindezela aphakeme kune-polyethylene.Izinga lokushisa layo lokubumba liyi-160 ~ 220 ℃, lingasetshenziswa cishe kumadigri ayi-100, futhi linezakhiwo ezinhle zikagesi kanye nokufakwa kwemvamisa ephezulu akuthintwa umswakama.Izinga layo lokumunca amanzi liphansi kune-polyethylene, kodwa kulula ukuncibilika ukuphuka komzimba, ukuthintana isikhathi eside nensimbi eshisayo kulula ukubola, ukuguga.I-fluidity yinhle, kodwa izinga lokuncipha lokubumba liyi-1.0 ~ 2.5%, izinga lokuncipha likhulu, okulula ukuholela embobeni yokuncipha, ukubola, ukuguqulwa nokunye ukukhubazeka.Isivinini sokupholisa se-polypropylene siyashesha, isistimu yokuthela kanye nesistimu yokupholisa kufanele iphole kancane, futhi inake ukulawula izinga lokushisa lokwakha.Ubukhulu bodonga bezingxenye zepulasitiki kufanele bufane ukuze kugwenywe ukuntuleka kweglue kanye ne-Angle ebukhali ukuvimbela ukuhlushwa kokucindezeleka.

1.2Ukuhlaziywa kwenqubo yokubumba ibhokisi lesidlo sasemini sepulasitiki

1.2.1.Ukuhlaziywa kwesakhiwo sezingxenye zepulasitiki

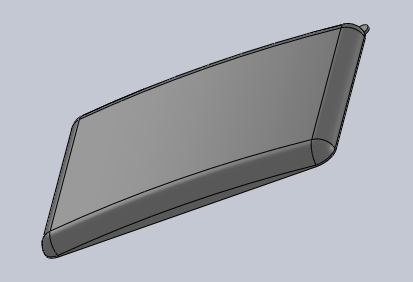

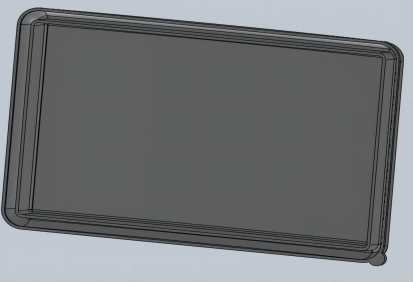

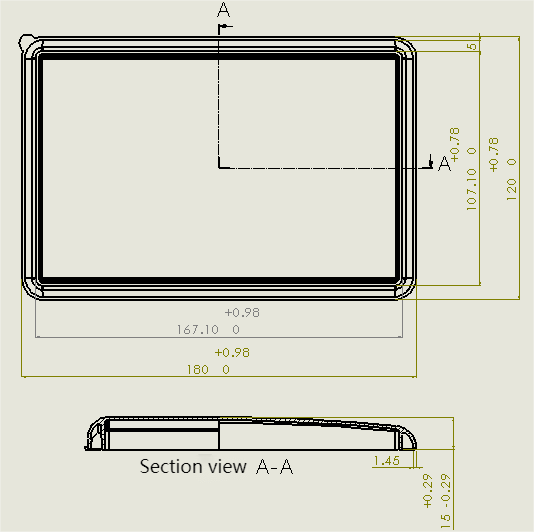

Ugqinsi olunconyiwe lodonga lwezingxenye zepulasitiki ezincane ze-polypropylene luyi-1.45mm;Usayizi oyisisekelo webhokisi lesidlo sasemini ngu-180mm×120mm×15mm;Thatha usayizi wangaphakathi wodonga lwekhava yebhokisi lesidlo sasemini: 107mm;Umehluko phakathi kwezindonga zangaphakathi nezingaphandle: 5mm;Ikhona eliyindilinga lodonga olungaphandle lingu-10mm, futhi ikhona eliyindilinga lodonga lwangaphakathi lingu-10/3mm.Ikhona elilodwa lekhava yebhokisi linomphathi we-annular one-radius engu-4mm.Ngenxa yokuthi izingxenye zepulasitiki ziyiziqukathi ezinodonga oluncane, ukuze kuvinjelwe ukuntuleka kokuqina namandla okubangelwa ukuguqulwa kwezingxenye zepulasitiki, ngakho-ke phezulu kwezingxenye zepulasitiki kuklanywe njengendilinga ye-arc ephakeme engu-5mm.

1.2.2.Ukuhlaziywa kokunemba kwe-Dimensional kwezingxenye zepulasitiki

Izilinganiso ezimbili zekhava yebhokisi lesidlo sasemini zinezidingo zokunemba, okungu-107mm no-120mm, futhi imfuneko yokunemba yi-MT3.Njengoba ubukhulu bangaphandle bezingxenye zepulasitiki buthintwa ukubekezelelana kobukhulu bengxenye enyakazayo yesikhunta (njengonqenqema olundizayo), uhlobo lokubekezelela lukhethwa njengebanga B. Uma izinga lokubekezelela lingadingeki, i-MT5 ikhethiwe. .

1.2.3.Ukuhlaziywa kwekhwalithi ephezulu yezingxenye zepulasitiki

Ukunemba okungaphezulu kwesembozo sebhokisi lokudla akuphakeme, futhi ubulukhuni obungaphezulu buka-Ra bungu-0.100~0.16um.Ngakho-ke, isikhunta esisodwa sokuhlukanisa isikhunta somjovo womgijimi wesango singasetshenziswa ukuqinisekisa ukunemba kwendawo.

1.2.4.Izinto ezibonakalayo kanye nevolumu kanye nekhwalithi yezingxenye zepulasitiki

Buza ngezinto ezibonakalayo zepulasitiki ye-PP (okuhlanganisa i-elastic modulus, isilinganiso se-Poisson, ukuminyana, amandla e-tension, ukuqhutshwa kwe-thermal nokushisa okuthile) ku-SolidWorks, futhi usebenzise isofthiwe ye-SolidWorks ukubala idatha yezingxenye zepulasitiki (okuhlanganisa isisindo, ivolumu, indawo kanye nendawo. amandla adonsela phansi).

1.3 Thola imingcele yenqubo yokubumba yezingxenye zepulasitiki

Enqubweni yokubunjwa komjovo, izinga lokushisa le-cylinder kanye ne-nozzle lizothinta i-plasticization kanye nokugeleza kwepulasitiki, izinga lokushisa lesikhunta lizothinta ukugeleza nokupholisa kokubunjwa kwepulasitiki, ingcindezi ekubunjweni komjovo izothinta ngqo plasticization of plastic kanye izingxenye zepulasitiki izinga.Ukukhiqizwa esimweni sokuqinisekisa ikhwalithi yezingxenye zepulasitiki kuzozama ukunciphisa umjikelezo wokubumba wezingxenye zepulasitiki, isikhathi sokujova kanye nesikhathi sokupholisa sibe nomthelela omkhulu kukhwalithi yezingxenye zepulasitiki.

Imibuzo okufanele icatshangelwe lapho uklama:

I-1) Ukusetshenziswa okufanele kweziqinisi, okokugcoba ukuze kuqinisekiswe ukusebenza kwenqubo yepulasitiki ye-PP kanye nokusetshenziswa kwezingxenye zepulasitiki.

I-2) Ukunciphisa, ukuhlehlisa, ukuguqulwa nokunye ukukhubazeka kufanele kuvinjelwe ngesikhathi sokuklama.

I-3) Ngenxa yejubane lokupholisa elisheshayo, qaphela ukuchithwa kokushisa kwesistimu yokuthulula kanye nesistimu yokupholisa, futhi unake ukulawulwa kokushisa okwenza.Lapho izinga lokushisa lesikhunta lingaphansi kwama-degree angu-50, izingxenye zepulasitiki ngeke zibe bushelelezi, kuzoba nokushisela okungalungile, ukushiya amamaki nezinye izenzakalo;Amadigri angaphezu kuka-90 athambekele ekuwohlokeni kwe-warp nezinye izenzakalo.

4) Ubukhulu bodonga bezingxenye zepulasitiki kufanele bufane ukuze bugweme ukuhlushwa kokucindezeleka.

1.4 Imodeli kanye nokucaciswa komshini wokubumba umjovo

Ngokusho kwemingcele yenqubo yokubumba yezingxenye zepulasitiki, ukukhetha kokuqala komshini wokubumba umjovo we-G54-S200/400 wasekhaya,

Ingxenye Yesibili: Idizayini yesakhiwo yesikhunta sokujova sekhava yebhokisi lepulasitiki lesidlo sasemini

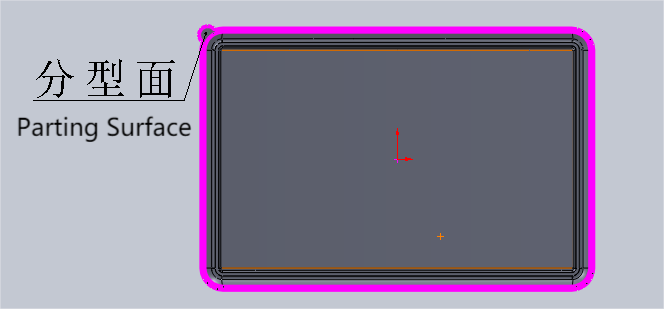

2.1 Ukunqunywa kwendawo yokuhlukanisa

Ukuma okuyisisekelo kanye nesimo sokudilizwa kwezingxenye zepulasitiki kufanele kucatshangelwe lapho kukhethwa indawo yokuhlukanisa.Izimiso zokuklama kwendawo yokuhlukanisa zimi kanje:

1. Indawo yokuhlukanisa kufanele ikhethwe ku-contour enkulu yengxenye yepulasitiki

2. Ukukhethwa kwendawo yokuhlukanisa kufanele kuhambisane nokudilizwa okushelelayo kwezingxenye zepulasitiki

3. Ukukhethwa kwendawo yokuhlukanisa kufanele kuqinisekise ukunemba kobukhulu kanye nekhwalithi ephezulu yezingxenye zepulasitiki kanye nezidingo zokusebenzisa kwazo.

4. Ukukhethwa kwendawo yokuhlukanisa kufanele kuhambisane nokucubungula nokwenza lula isikhunta

5. Nciphisa indawo yokuqagela yomkhiqizo lapho uqondana khona ne-clamping

6. Umgogodla omude kufanele ubekwe ohlangothini lokuvula ukufa

7. Ukukhethwa kwendawo yokuhlukanisa kufanele kuhambisane nokukhipha umoya

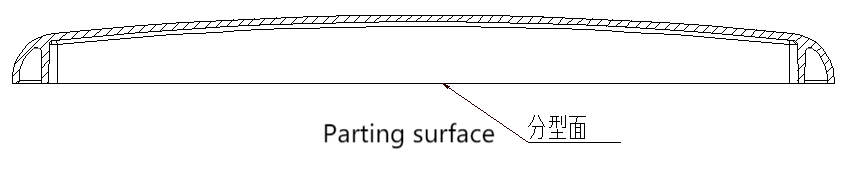

Ukufingqa, ukuze kuqinisekiswe ukudilizwa okubushelelezi kwezingxenye zepulasitiki kanye nezidingo zobuchwepheshe zezingxenye zepulasitiki kanye nokukhiqizwa okulula kwesikhunta, indawo yokuhlukanisa ikhethwa njengendawo engezansi yesembozo sebhokisi lesidlo sasemini.Njengoba kukhonjisiwe emdwebeni ongezansi:

2.2 Ukunqunywa kwenombolo ye-Cavity kanye nokucushwa

Ngokwezidingo zokuklama zezingxenye zepulasitiki zokuklama imanuwali, izingxenye zepulasitiki izici zesakhiwo sejometri kanye nezidingo zokunemba kobukhulu kanye nezidingo zezomnotho zokukhiqiza, zinquma ukusetshenziswa kwesikhunta imbobo.

2.3 Idizayini yesistimu yokuthela

Lo mklamo usebenzisa uhlelo olujwayelekile lokuthulula, futhi izimiso zokuklama zalo zimi kanje:

Gcina inqubo imfushane.

Ukuphefumula kufanele kube kuhle,

Vimbela i-core deformation bese ufaka ukususwa,

Vimbela ukuwohloka kwezingxenye zepulasitiki kanye nokwakheka kwezibazi ezibandayo, izindawo ezibandayo nezinye iziphambeko ebusweni.

2.3.1 Ukwakhiwa kwesiteshi esikhulu

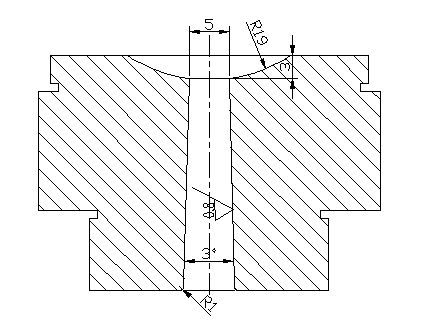

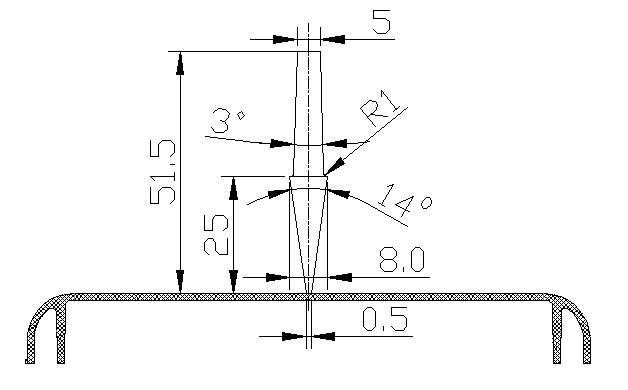

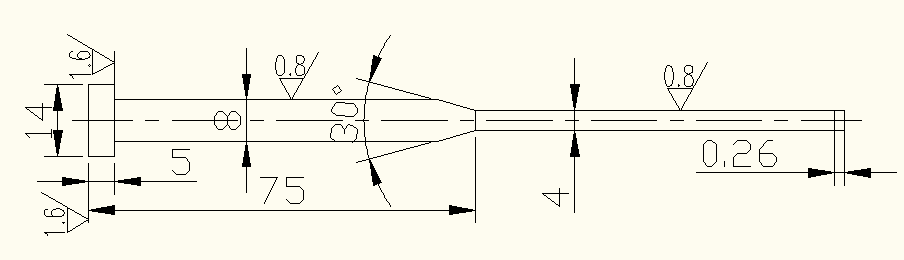

Isiteshi esikhulu sakhelwe ukuthi sibe yikhonikhi, kanti i-cone Angle α ingu-2O-6O, kanye no-α=3o.Ubukhulu obungaphezulu besiteshi sokugeleza i-Ra≤0.8µm, ukuphuma kwesiteshi esikhulu kuyinguquko ye-fillet, ukuze kuncishiswe ukumelana kokugeleza kwezinto ezibonakalayo ekuguqukeni, i-fillet radius r = 1 ~ 3mm, ithathwa njenge-1mm. .Isakhiwo sesiteshi esikhulu simi kanje;

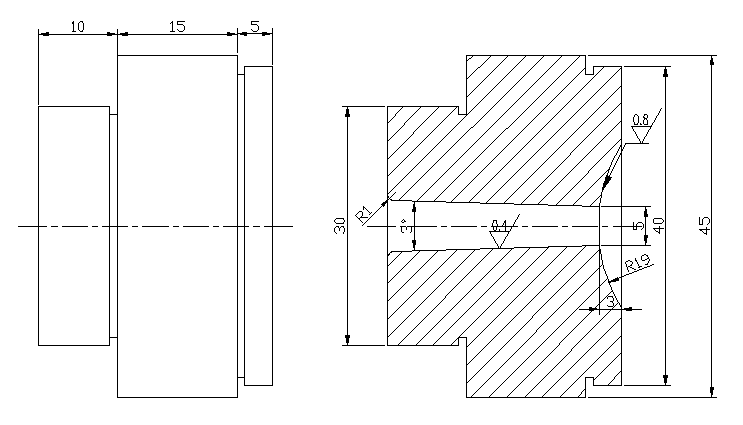

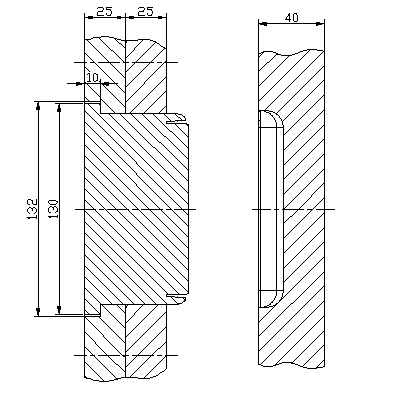

Isakhiwo somkhono wesango siklanywe saba izingxenye ezimbili kusetshenziswa umkhono wesango kanye nendandatho yokubeka indawo, egxilwe epuleti lesihlalo sokufa esigxilile ngendlela yesinyathelo.

Ububanzi bomkhawulo omncane womkhono wesango bukhulu ngo-0.5 ~ 1mm kunombobho, othathwa njengo-1mm.Njengoba ingaphambili lendawo encane iyindilinga, ukujula kwayo kungu-3 ~ 5mm, okuthathwa njengo-3mm.Njengoba i-sphere ye-nozzle yomshini womjovo ithintana futhi ilingana nesikhunta kule ndawo, ububanzi bendilinga yesiteshi esikhulu kudingeka ukuthi bube bukhulu ngo-1 ~ 2mm kunombobho, othathwa njengo-2mm.Ifomu lokusebenzisa kanye nemingcele yomkhono wesango kukhonjisiwe ngezansi:

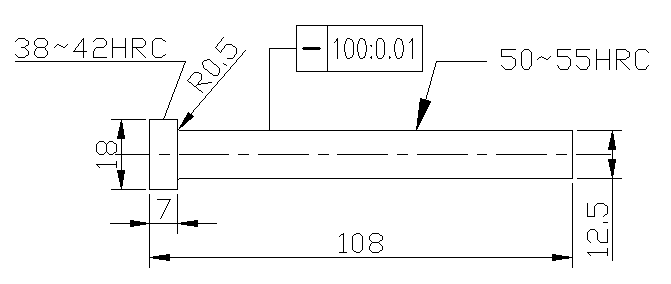

Ukulingana koshintsho lwe-H7/m6 kwamukelwa phakathi komkhono wesango nesifanekiso, futhi ukulingana kwe-H9/f9 kwamukelwa phakathi komkhono wesango nendandatho yokuma.Indandatho yokumisa ifakwa embotsheni yokumisa isifanekiso esimisiwe somshini womjovo ngesikhathi sokufakwa nokulungiswa kwamaphutha kwesikhunta, esisetshenziselwa ukufakwa nokubeka isikhunta nomshini womjovo.Ububanzi obungaphandle bendandatho yokumisa buncane ngo-0.2mm kunembobo yokubeka esifanekisweni esigxilile somshini womjovo, ngakho-ke ingu-0.2mm.Ifomu elimisiwe lomkhono wesango kanye nosayizi wendandatho yokuma kuboniswe ngezansi:

2.3.2 Shunt ukwakheka kweshaneli

Ngoba umklamo uyisikhunta imbobo, indawo yokuhlukanisa phansi kwesembozo sebhokisi, kanye nokukhethwa kwesango lohlobo oluqondile lwesango, ngakho-ke i-shunt akudingeki ukuba iklame.

2.3.3 Idizayini yesango

Ukucabangela izidingo zokubumba izingxenye zepulasitiki kanye nokucubungula isikhunta kulula noma cha futhi ukusetshenziswa kwangempela kwesimo, ngakho-ke ukuklama kwendawo yesango kukhethwe njengesikhungo esiphezulu sekhava lebhokisi lesidlo sasemini.Ububanzi besango lephoyinti ngokuvamile bungu-0.5 ~ 1.5mm, futhi buthathwa njengo-0.5mm.I-engeli α ivamise ukuba ngu-6o~15o, futhi ithathwa njengo-14o.Umklamo wesango uboniswe ngezansi:

2.4 Idizayini yembobo ebandayo nenduku yokudonsa

Ngakho-ke, umklamo uyisikhunta kanye nomgodi, isango lokukhomba ukuthululwa okuqondile, ngakho-ke imbobo ebandayo kanye nenduku yokudonsa akudingeki ukuthi iklanywe.

2.5 Ukuklanywa kwezingxenye zokwakha

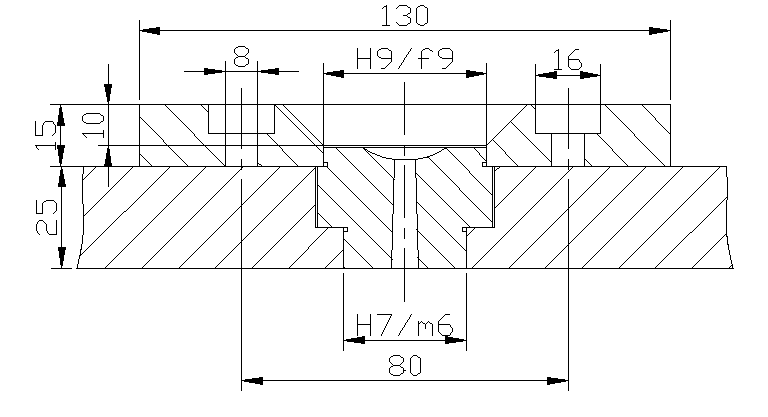

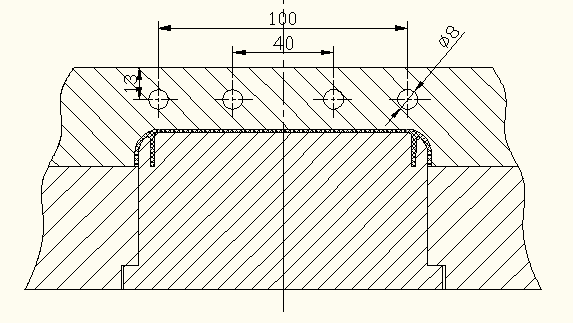

2.5.1Ukunqunywa kwesakhiwo se-die and punch

Ngenxa yokuthi iyingxenye encane yepulasitiki, i-cavity, futhi ukuze kusetshenziswe kahle kakhulu, ukuhlakazeka okulula, kodwa futhi nokuqinisekisa ukunemba nobukhulu bezingxenye zepulasitiki, umklamo we-convex jikelele kanye nokukhethwa kwe-concave die lonke.I-convex die icutshungulwa ngendlela ehlukile yokucubungula, bese icindezelwa kusifanekiso ngoshintsho lwe-H7/m6.Umdwebo womklamo wesakhiwo se-convex kanye ne-concave die umi kanje:

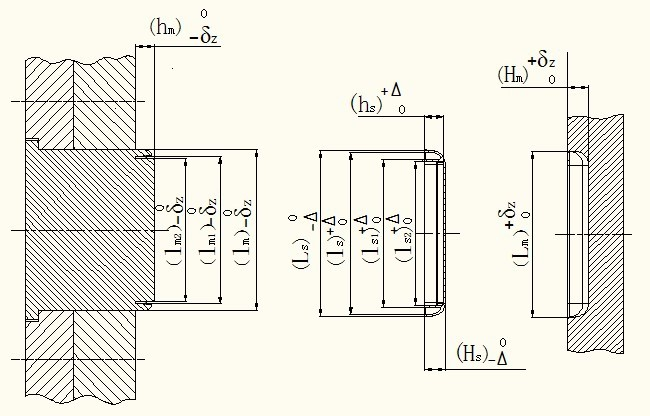

2.5.2Ukuklama nokubala komgodi kanye nesakhiwo esiyinhloko

Ubudlelwano phakathi kosayizi wokusebenza wengxenye yesikhunta kanye nosayizi wengxenye yepulasitiki kuboniswe ngezansi:

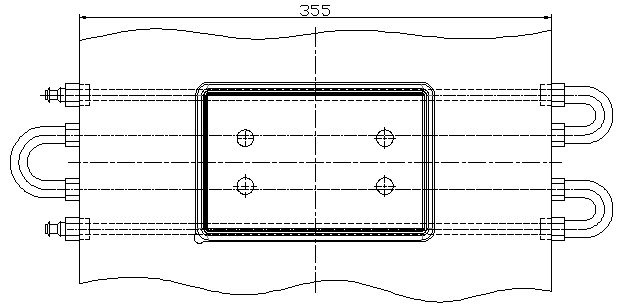

2.6 Ukukhethwa kwefreyimu yesikhunta

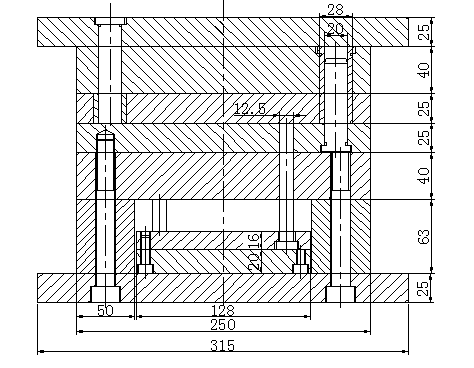

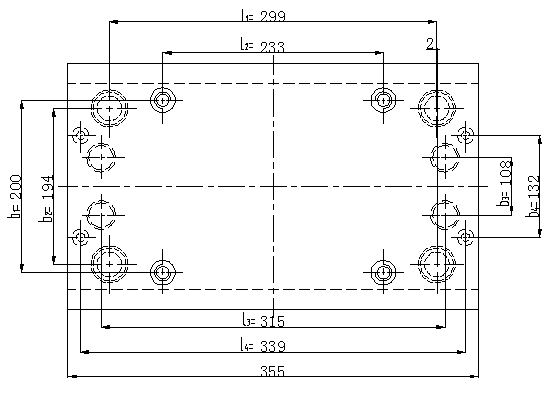

Njengoba lo mklamo ungowezingxenye zepulasitiki ezincane neziphakathi, uhlaka lwesikhunta luyi-P4-250355-26-Z1 GB/T12556.1-90, kanti i-B0×L yohlaka lwesikhunta yi-250mm×355mm.

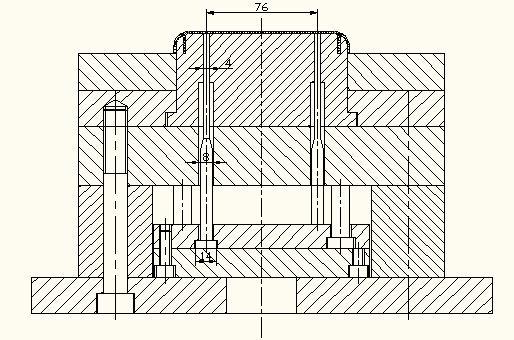

Umdwebo wokuhlanganisa isikhunta umi kanje:

2.7 Isakhiwo sengxenye yesakhiwo

2.7.1Idizayini yesakhiwo sekholomu yomhlahlandlela

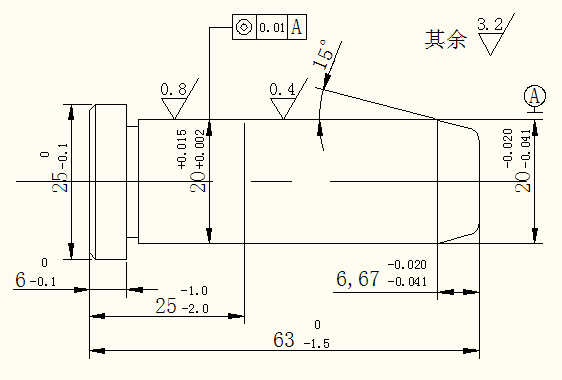

Ububanzi bepali yomhlahlandlela ngu-Φ20, futhi impahla ekhethelwe isiqondisi yinsimbi engu-20, ene-carburizing engu-0.5~0.8mm kanye nobulukhuni bokucisha obungu-56~60HRC.I-Angle e-chamfered eboniswe emfanekisweni ayikho ngaphezu kwe-0.5×450.Iposi eliwumhlahlandlela limakwe ngokuthi Φ20×63×25(I) — 20 steel GB4169.4 — 84. Ukulingana koshintsho lwe-H7/m6 kwamukelwa phakathi kwengxenye engashintshi yekholomu yomhlahlandlela nesifanekiso.Enye iposi yomhlahlandlela imakwe Φ20×112×32 — 20 steel GB4169.4 — 84.

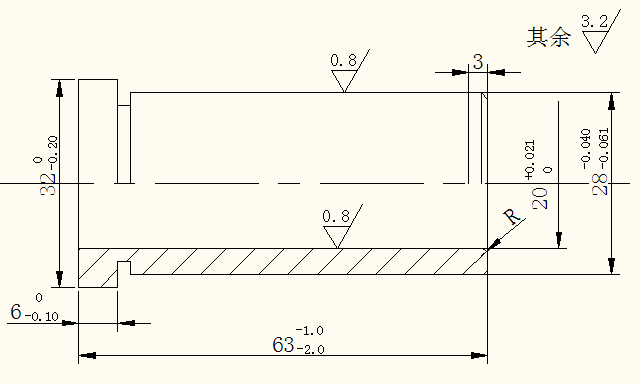

2.7.2Umhlahlandlela wesakhiwo somkhono wesakhiwo

Ububanzi bomkhono womhlahlandlela ngu-Φ28, futhi impahla yomkhono womhlahlandlela iyinsimbi engu-20, i-carburized 0.5~0.8mm, futhi ukuqina kokwelashwa okucinyiwe kungu-56~60HRC.I-chamfering eboniswe esithombeni ayikho ngaphezu kwe-0.5 × 450.Umkhono womhlahlandlela umakwe ngokuthi Φ20×63(I) — 20 steel GB4169.3 — 84, futhi ukunemba okufanayo kweposi lomhlahlandlela nomkhono womhlahlandlela ngu-H7/f7.Omunye umkhono womhlahlandlela obhalwe ukuthi Φ20×50(I) — 20 steel GB4169.3 — 84.

2.8 Yethula idizayini yemishini

Indlela yokuphusha ngokuvamile yakhiwa ukusunduza, ukusetha kabusha kanye nokuqondisa.

Ngenxa yokuthi izingxenye zepulasitiki zincane, uma uzama ukuqinisekisa ikhwalithi yokubukeka kwezingxenye zepulasitiki, umklamo womshini wokuqalisa usebenzisa induku ye-ejector ukuze iphushe izingxenye zepulasitiki.

Umdwebo wohlelo lwendlela yokuqalisaimi kanje:

Isakhiwo kanye nemingcele ye-push rodkuboniswe ngezansi:

Ifomu lesakhiwo namapharamitha wenduku yokusetha kabushakuboniswe ngezansi:

2.9 Idizayini yesistimu yokupholisa

Njengoba ukupholisa kungekona okufanayo, uhlelo lokupholisa lwesiteshi sokupholisa kufanele lube ngangokunokwenzeka, lokhu kukhetha kokuklama kwe-4. Ibanga lesiteshi ukusuka endaweni ye-cavity lilingana, futhi i-sprue nayo iqiniswa ukupholisa.Uhlelo lokupholisa lusebenzisa uhlobo lokujikeleza kwe-DC, olunesakhiwo esilula nokucubungula okulula.

Idizayini yesistimu yokupholisa imi kanje:

Ingxenye Yesithathu: Hlola ukubalwa kwesikhunta somjovo

3.1.Hlola imingcele yenqubo ehlobene yomshini womjovo

3.1.1 Hlola umthamo omkhulu womjovo

3.1.2 Hlola amandla okubamba

3.1.3 Hlola uhambo lokuvula isikhunta

3.2.Hlola ukujiya kodonga oluseceleni kanye nepuleti elingezansi le-caviar engunxande

3.2.1 Hlola ukujiya kodonga oluseceleni lwembobo ehlangene engunxande

3.2.2 Hlola ukujiya kwepuleti elingaphansi elingunxande

isiphetho

Umklami weqembu leFreshness Keeper u-Xie Master lo mklamo ungowokwakhiwa kwesikhunta sesembozo sebhokisi lesidlo sasemini sepulasitiki, ngokuhlaziywa kwempahla yesembozo sebhokisi lesidlo sasemini, ukwakheka kwezingxenye zepulasitiki nobuchwepheshe, bese kuba okunengqondo, ukuphothulwa kwesayensi komjovo. umklamo.

I-Freshness Keeper Izinzuzo zomklamo ukwenza lula indlela yokubumba umjovo ngangokunokwenzeka ukuze kuqinisekiswe ikhwalithi yezingxenye zepulasitiki, ukunciphisa umjikelezo wokubumba, izindleko zokukhiqiza eziphansi.Amaphuzu abalulekile omklamo inqubo yokubumba umjovo, ukwakheka komgodi, ukukhethwa kwendawo yokuhlukanisa, isistimu ye-gating, indlela yokukhipha, indlela yokudonsa, uhlelo lokupholisa, ukukhethwa komshini wokubumba umjovo kanye nokuhlolwa kwemingcele efanele kanye nomklamo wezingxenye eziyinhloko.

Umklamo okhethekile we-Freshness Keeper ulele ekwakhiweni kwesistimu yokuthulula, ukuthululela umkhono wesango lesistimu kanye nendandatho yokubeka ingxenye eyodwa, ukuqinisekisa impilo yesikhunta, nokukhethwa kwezinto ezibonakalayo, ukucubungula, ukwelashwa kokushisa kanye nokushintshwa kulula;Isango liwuhlobo oluqondile lwesango, oludinga indawo ephindwe kabili yokuhlukanisa, futhi i-drawplate yebanga elingashintshi isetshenziselwa ukukhawulela ukuhlukana kokuqala.Isakhiwo silula futhi sinengqondo.

Isikhathi sokuthumela: Nov-01-2022